Material Of Jacket Is S30408 Screw Diameter Is 400mm Raw Material

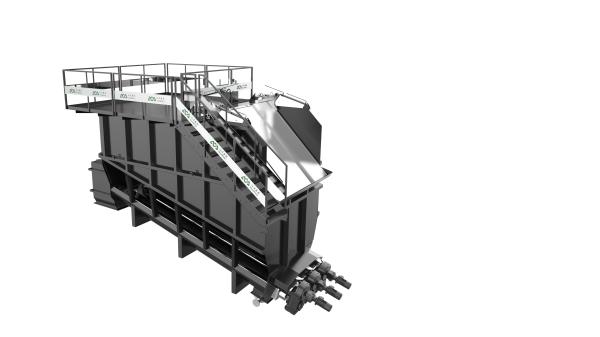

Hopper

Raw Material Bins& Silo

The product line of bins includes raw material to meal bins and

everything in between.

No matter what kind of meat, poultry or fish by-products you

process, you will always need simple, rugged bins for moving,

parking and storing everything from raw material and other inputs

to your finished output.

They’re a big help in the practicalities of process management,

proving you with a low-tech buffer between individual processing

lines and pieces of equipment, and helping ensure good flows and

maximum flexibility.

The bins and silos are tough and durable, designed to prevent leaks

and ensure compliance with appropriate hygiene standards.

Arrangement plan This scheme is mainly used in the occasion of one

material and one scale. In this case, all the raw materials are

weighed The aggregate belt is fed into the mixer. The aggregate

belt can pre-mix various raw materials. The biggest advantage of

this method is that the order of the various raw materials entering

the mixer can be arranged reasonably.

Production practice shows that, among the factors that affect the

uniformity of the mixing of batch materials, the order of adding

raw materials to the mixer has a very important effect. The order

in which the raw materials are added to the mixer is exquisite.

First of all, it is necessary to ensure that the raw materials can

be mixed in the batch to the fullest without interference from

other raw materials. In addition, it is necessary to consider as

much as possible to make the layering effect of coarse-grained raw

materials less obvious. This requirement for sequence determines

the arrangement of bins, feeders and scales in the weighing system,

as shown in the figure.

The advantage of arranging the warehouse is flexible and

convenient, the number of silos can be increased or decreased at

will, and the maintenance is convenient. The disadvantage is that

it covers a large area, the concrete volume of the plant is large,

the horizontal conveying distance is long, the energy consumption

is large, and the corresponding dust collection point increases,

which increases the construction cost. However, due to its

outstanding advantages and reasonable cutting order, which is more

conducive to the homogenization of batch materials, most

manufacturers still adopt this arrangement.

| designed volume | 35m³ |

| input format | side input |

| screw diameter | 400mm |

| screw quantity | 2.Pcs |

| material for body | carbon steel |

| hydraulic cover material | stainless steel |

| motor power | 2*5.5kw |

| motor brand | Simens |

| Reducer brand | JIE |

| shaft brand | SKF |

| shipping weight | 18000kg |